vickers hardness test steps|vickers microhardness test procedure : maker The general principle of the Vickers and Knoop indentation hardness test consists of two steps: Step 1 - The applicable specified indenter is brought into contact with the test specimen in a . webOs Sacanas Filminho - Todos os Filminhos . Os Sacanas Filminho 24 . . vídeos, ilustrações, etc.) de todas as Atrações do 'TUFOS - Mega Portal Adulto' são protegidas pela LEI DO DIREITO AUTORAL, não sendo permitidas cópias ou divulgações por qualquer motivo ou justificativa, nem mesmo com autorização das(os) modelos. Infratores .

{plog:ftitle_list}

WEBCheck out our dolphin pearl ring selection for the very best in unique or custom, handmade pieces from our statement rings shops.

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .The general principle of the Vickers and Knoop indentation hardness test consists of two steps: Step 1 - The applicable specified indenter is brought into contact with the test specimen in a .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.

Designed for the accurate hardness testing of small precision parts, thin materials, case hardened layers and all sorts of steel components. The Phase II 900-398 is our macro-Vickers . What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .Procedure for Conducting the Vickers Hardness Test. To conduct a hardness test, the following steps are generally followed: Sample Preparation: The material sample should be smooth & .

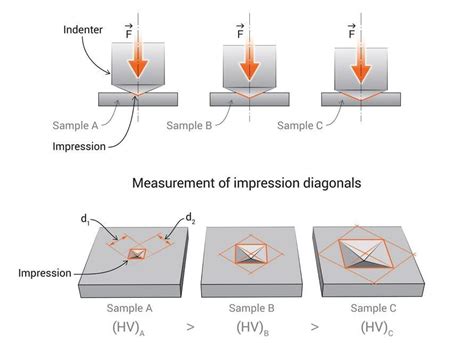

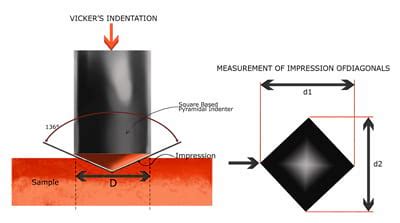

During the Vickers Hardness test, a pyramid-shaped diamond indenter is used to create a permanent indentation in the material under test by applying a specific load. This .Here's the article for you to everything about Vickers hardness testing, including basics and principle, Vickers hardness test procedure, formula and calculation. + 86 755 61301520 [email protected] For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the .

Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method. The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.

The Wilson® VH1150 Vickers Series Hardness Testers offer a versatile and user friendly solution for a wide range of hardness scale testing. For single scale hardness testing, the Wilson VH1150 Tester is equipped with a five-position turret which includes one indent- . Test Load range 300gf - 50kgf Test load steps 0.3 – 0.5 – 1 – 2 - 3 . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.

The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. . Steps for The Test 3.1 Sample Preparation. To ensure accurate results, the test surface must be flat, smooth, and free from contaminants. . Table 2: Brinell, Rockwell & Vickers Hardness Conversion . EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 - Standard Vickers hardness test method for testing metals and materials with a medium to high hardness range. 1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

vickers microhardness test procedure

The Vickers hardness number is the load (test force) over the resulting area of the diamond impression, and can be calculated by the formula: HV = F ≈ . . . The Vickers hardness test, an offshoot of the venerable Brinell test, has been used since the early 1920s. . This step is necessary for most testers to make the indent as indenter .

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surfaceVickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; . Step-by-step Guide to the Hardness Testing Procedure . Here's a step-by-step instruction to guide you through a standard hardness testing procedure, in this case, we'll use the commonly used Rockwell hardness testing method as our guide: .The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is .

In the second step, the main force is applied to the sample. Most of the time the main force is held for 7 seconds. Depen-ding on the method chosen, the forces used may be different. . The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements,

Experimental rolling of copper strips (M0) on a 150×235 mill was carried out followed by testing of the material to determine the yield strength (deformation resistance), tensile strength (time resistance) and percent elongation, as well as measuring the Vickers hardness (HV) of the annealed (non-cold-worked) and deformed samples from the strips after cold .The ultimate macro-vickers hardness tester is the Wilson VH1150 Macro vickers Hardness Tester. Boasting a unique load range of 300gf – 50kgf, enjoy its user-friendly operation with automatic load selection . Test load steps 0.3 – 0.5 – 1 – 2 - 3 -5 – 10 – 20 – 30 – 50kgf Test Load Accuracy ±1.5% : 200g, ±1% > 200g Force .In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.Vickers hardness testing is extensively used in the metals and alloys industry to evaluate different metallic materials' hardness, strength, and durability. This instrument helps evaluate metallic components' hardness, strength, and durability, ensuring they meet the required specifications and standards. 2. Automotive and Aerospace

We want to ensure certainty across every step of your preparation process. By providing everything you need to optimize your lab results, we help to make your ambitions a reality and a success. . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves . Here’s a step-by-step of the process: Apply preliminary load. Start by applying a minor load of 10 kgf to the material. . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable for micro hardness testing .

1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:

(III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.Step 2 - For the Vickers hardness test, the lengths of the two diagonals are measured and the mean diagonal length is calculated, which is used to derive the Vickers hardness value. For the Knoop hardness test, the length of the long diagonal is measured, which is used to derive the Knoop hardness value. .

vickers hardness test procedure

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.

where α is the percentage crystallinity; H C is the hardness of fully crystalline PP, and H A is the hardness of fully amorphous PP. Using hardness testing with loads of 0.25 and 0.5 N and with a loading cycle of 0.1 min, Martinez Salazar et al. were able to extrapolate to show H C = 30 MPa and H A = 116 MPa. Whereas, this is useful information, there is ambiguity with .

WEBLivesport.com: os mais rápidos e precisos placares ao vivo de futebol, tênis, basquete, beisebol, hóquei e muitos outros esportes. Placar ao vivo, resultados, estatísticas. Siga os TOP SCORES na página inicial - placar ao vivo e últimos resultados as partidas mais importantes de todos os esportes juntos em uma só página.

vickers hardness test steps|vickers microhardness test procedure